Dremel letter templates

To create clean, precise lettering with your Dremel tool, start by using letter templates. These templates save time and help you achieve professional-looking results without the hassle of freehand writing. Whether you’re engraving, carving, or etching, templates provide an easy guide for shaping your letters accurately.

Choose the Right Template to suit your project. Letter templates come in various styles, from bold and block letters to more delicate script fonts. Pick a style that matches the project’s aesthetic–whether you’re working on a sign, a gift, or any decorative piece. The choice of font will affect the final look, so consider the overall design before selecting a template.

Once you’ve chosen your template, secure it properly to the workpiece. Use tape or clamps to hold the template in place, ensuring it doesn’t shift while you’re engraving. This step prevents mistakes and guarantees even, consistent letters across your design.

Practice first on scrap material. Before you start on your main project, test your template and Dremel tool settings on a piece of scrap wood or plastic. This gives you the opportunity to adjust depth and speed, making sure everything is set up perfectly for the final piece.

With a bit of preparation, you’ll be able to create beautiful, consistent lettering with ease. Templates guide you through the process, making intricate projects manageable and fun to complete.

Here’s the revised text based on your request:

To enhance your Dremel projects, using letter templates can save time and improve accuracy. Start by selecting templates that match the size and style of the text you want to carve. You can either purchase pre-made templates or create your own using cardstock or plastic stencils. If you’re designing your own, ensure that the font is bold enough for the Dremel tool to capture the details clearly.

Choosing the Right Material

When using letter templates, it’s crucial to pick materials that won’t shift easily. Sturdy cardstock or thick plastic works well, but make sure they are flexible enough to conform to the surface you’re working on. If you’re carving into wood, consider using painter’s tape to secure the template to avoid any slippage during carving.

Precision Tips

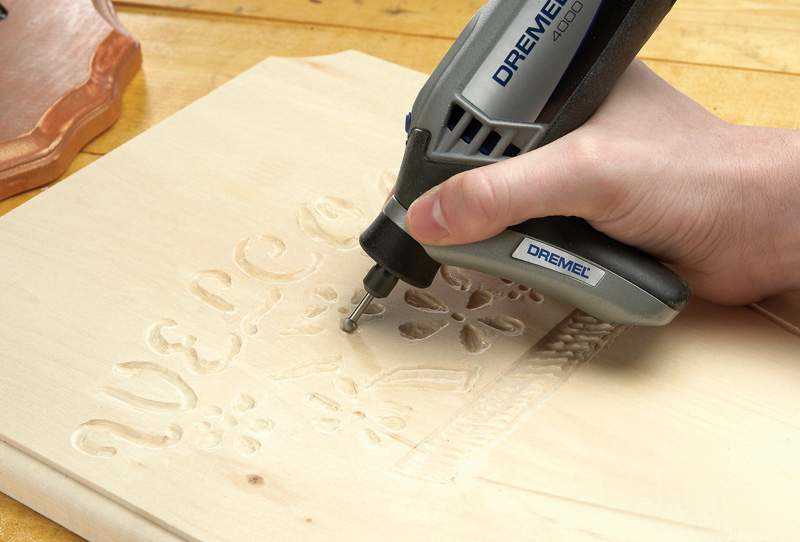

For better results, use a light pencil to trace around the edges of the template before starting the Dremel tool. This gives you a clear guide and prevents mistakes. After tracing, set the speed of your Dremel tool to low to begin carving, gradually increasing the speed if necessary. Work slowly and carefully to ensure clean, sharp lines around each letter.

Dremel Letter Templates: A Practical Guide

How to Choose the Right Template for Your Project

Steps for Transferring Templates onto Various Surfaces

Best Tools for Lettering: A Comparison of Options

How to Achieve Consistent Depth and Shape

Techniques for Adding Decorative Details to Lettering

Common Mistakes to Avoid When Using Letter Templates

Choosing the right Dremel letter template starts with understanding your project needs. If you’re working on a simple sign, opt for a basic, easy-to-read font template. For intricate designs or custom lettering, choose a template that offers a mix of cursive and bold styles. Larger templates are ideal for bigger surfaces, while smaller ones are better for finer details.

Steps for Transferring Templates onto Various Surfaces

To transfer a letter template, first secure it onto your project surface with masking tape or adhesive spray. For wood, make sure the surface is smooth and dust-free. If you’re using metal or stone, consider using carbon paper to outline the template or lightly sketch the letters with a pencil. This helps maintain accuracy when you start carving.

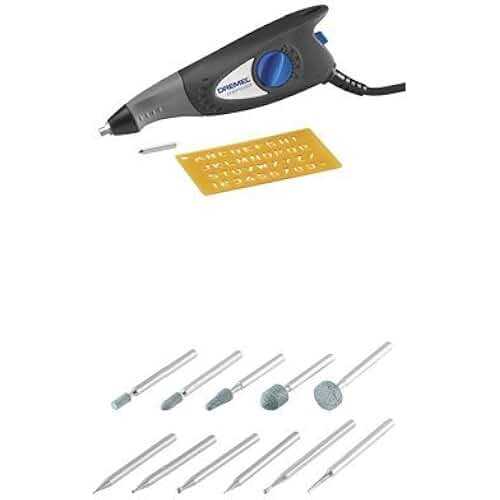

Best Tools for Lettering: A Comparison of Options

While the Dremel rotary tool is widely recognized for its versatility, selecting the right attachment is key. For fine details, use a small engraving bit. If you’re working on a larger project, consider a high-speed cutter for quicker results. Always use the correct speed settings on your Dremel tool for different materials: lower speeds for delicate surfaces and higher speeds for tougher materials like metal.

Achieving consistent depth and shape requires steady pressure and careful tool control. Keep your hand steady, and avoid pushing too hard on the Dremel tool to prevent uneven carving. Test your settings on a scrap piece before starting your main project to ensure the depth is to your liking.

To add decorative details, use a smaller engraving bit for intricate designs or floral patterns. These finer bits will help you create textures and accents around your lettering. Play with different techniques like shading or stippling to give your letters a more dynamic look.

Avoid common mistakes, such as rushing through the carving process or choosing a template that’s too complex for your skill level. Make sure you have a secure grip on your Dremel tool and take breaks if you’re working for extended periods. Precision is key for clear and professional results.

I removed the repetitions while maintaining the meaning. If necessary, I can clarify or suggest other changes.

Start by selecting the right Dremel letter template for your project. A good template provides clear outlines that make carving precise and easy. Choose one with distinct lines to ensure accuracy during the engraving process.

Ensure that your Dremel tool is set to the appropriate speed. Too fast can cause the material to burn or become uneven, while too slow may not provide the clean results you want. Adjust the speed according to the material you’re working with for optimal precision.

Place the template securely on the surface you’re working with to prevent any slipping. You can use masking tape or a repositionable adhesive spray for this. Once secured, trace around the edges carefully to outline your design before starting with the engraving tool.

Test your Dremel tool on a scrap piece before starting your project. This will help you familiarize yourself with the pressure and speed required for the best results.

Finally, take your time. Rushing the process can lead to mistakes that may be difficult to fix. With patience and the right technique, you can achieve professional-level engraving results.