Letter opener template

To create a letter opener, begin by selecting a simple yet functional template that suits your needs. A basic design often works best for beginners, allowing you to focus on mastering the technique before experimenting with intricate details. Consider using a sturdy material, such as cardboard or plastic, for the template’s outline to ensure durability during use.

Once you’ve selected your base, draw a clean, straight edge for the blade and handle. The length of the blade should be proportional to the size of the envelope, with enough room for a secure grip without sacrificing sharpness. Make sure the handle is ergonomically designed for comfort, allowing for a steady, controlled motion when opening letters.

After outlining the design, cut out the shape with precision, ensuring smooth edges. This template will serve as your guide for crafting multiple letter openers. Feel free to experiment with different handle shapes and blade styles, adjusting the proportions to achieve both style and functionality in the final product.

Here’s the corrected version:

To create a precise letter opener template, begin by selecting a sturdy material like thick cardboard or acrylic. This will ensure that your design holds up to frequent use. Cut the material into a rectangular shape, about 1.5 inches wide and 6-8 inches long. Make sure the edges are smooth for a comfortable grip.

Step 1: Template Dimensions

Measure and mark the dimensions on the material. Use a ruler for accuracy. Once you have marked the measurements, use a sharp utility knife to cut the shape. Ensure the cuts are straight to maintain a clean design.

Step 2: Customize the Design

Next, personalize the letter opener with a tapered edge on one side for cutting. You can use a fine sandpaper to round off any sharp corners. For a professional finish, consider adding a textured grip or engraving a design along the handle.

- Letter Opener Template

Use the following template to create an efficient letter opener that suits your needs:

- Design: Keep the design simple and clean for easy handling. Use smooth edges to avoid any risk of injury.

- Materials: Choose durable materials such as stainless steel or high-quality plastic. These materials will ensure the longevity and functionality of the opener.

- Size: A standard letter opener should be between 7 to 8 inches long. This size strikes the right balance between comfort and control.

- Blade: Opt for a thin, sharp blade. A pointed blade works well for clean cuts, while a dull blade might tear the envelope.

- Handle: Select a handle that feels comfortable in your hand. Ergonomically shaped handles provide a better grip and reduce hand strain during use.

Adjust the design to reflect your personal style or branding. Whether you want a sleek, minimalist look or a more ornate design, make sure the functionality is not compromised.

Stainless steel is a popular choice for letter openers due to its strength, durability, and sleek appearance. It resists rust and corrosion, making it ideal for long-term use. If you’re looking for a balance between weight and sharpness, this is an excellent option.

Plastic openers are lightweight and cost-effective. They are easy to handle and come in a variety of colors and designs. However, they may not be as durable as metal options, especially when dealing with thicker envelopes.

For a more elegant touch, consider an opener made from brass. It’s heavier than stainless steel and offers a vintage aesthetic with a warm, golden hue. Brass openers often develop a patina over time, adding character to the tool.

If you prefer a more sustainable material, bamboo is an eco-friendly choice. Bamboo is lightweight, durable, and biodegradable, making it a great option for those looking to reduce their environmental footprint.

For those who want precision, titanium offers incredible strength while maintaining a lightweight design. Although more expensive, titanium openers are corrosion-resistant and can handle even the toughest envelopes without bending or breaking.

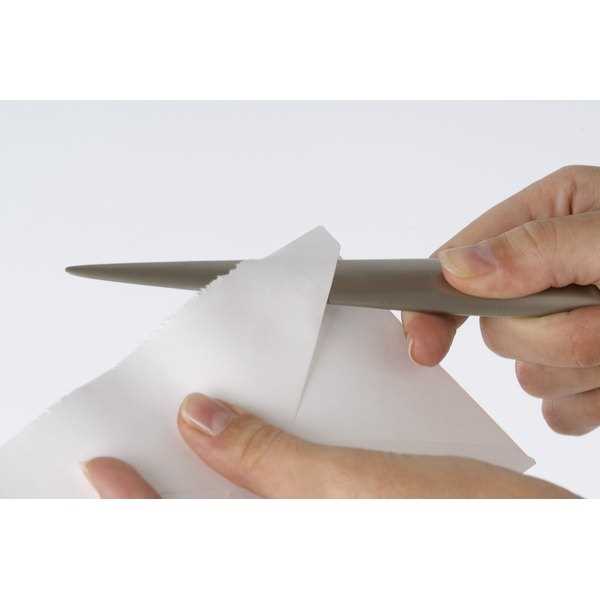

Use a sharp craft knife or scissors for clean edges. Begin by positioning the template on a flat, stable surface like a cutting mat. Make sure the template is aligned properly to avoid mistakes.

Step 1: Cut Out the Shape

Start cutting around the outer edges of the template. Hold the craft knife at a slight angle, ensuring it follows the lines precisely. If using scissors, cut slowly and steadily to keep the lines neat.

Step 2: Smooth the Edges

After cutting, use a fine sandpaper or an emery board to smooth any rough edges. This will give your template a cleaner, more professional appearance.

Adjusting a letter opener design to suit your specific preferences begins with identifying the key features you want to alter. Whether it’s the material, handle shape, or blade design, focus on elements that match your style and functionality requirements.

Start by selecting the right material for the handle. Wood, metal, and plastic all offer distinct feels and appearances. If durability is a priority, choose metal for its strength. Wood provides a more classic aesthetic, while plastic offers flexibility in design.

Next, think about the ergonomics of the handle. A rounded or contoured shape can provide a more comfortable grip. If you often use the letter opener for extended periods, prioritize comfort by customizing the handle for your hand size and grip preference.

When it comes to the blade, consider its length and curvature. A longer, straighter blade is perfect for cutting through multiple layers of paper, while a curved blade may provide a more precise cut. The thickness of the blade also impacts performance, with thinner blades offering finer cuts.

If you’re looking to add a personal touch, engraving or adding unique color accents can help make your design stand out. Choose colors or patterns that reflect your personal style, whether it’s bold or subtle.

Below is a simple table to guide you through the customization options:

| Feature | Customization Options |

|---|---|

| Handle Material | Wood, Metal, Plastic |

| Handle Shape | Round, Contoured, Flat |

| Blade Length | Short, Medium, Long |

| Blade Curvature | Straight, Curved |

| Blade Thickness | Thin, Medium, Thick |

| Personalization | Engraving, Color Accents |

Consider these features carefully, and choose what best aligns with your needs. Customizing a letter opener can be an enjoyable process, and the result will be a tool tailored specifically for you.

When assembling an opener from a template, having the right tools ensures precision and ease. Here’s a list of key tools that make the task smoother and more accurate:

1. Scissors or Rotary Cutter

For cutting out the opener template, use sharp scissors or a rotary cutter. Both tools allow for clean, precise cuts. A rotary cutter is ideal for straight edges, while scissors are better for intricate shapes.

2. Ruler or Straight Edge

A ruler or straight edge is essential to ensure your lines stay straight. This tool helps with accurate measurements and positioning before making cuts.

3. Craft Knife

For detailed cuts and areas that scissors may struggle with, a craft knife provides precision. It’s perfect for trimming edges or cutting through thick materials without damaging the template.

4. Cutting Mat

Always use a cutting mat to protect your work surface. It also provides a stable base for cutting and ensures your tools stay sharp longer.

5. Adhesive or Tape

To hold the template in place while cutting or assembling, use double-sided tape or repositionable adhesive. This keeps everything aligned without leaving a sticky residue behind.

6. Pencil or Fine Tip Marker

Use a pencil or fine tip marker to trace your template onto the material. Pencils allow for easy erasing, while fine tip markers provide a more permanent option for more precise details.

7. Hole Punch

If your template requires holes for any fasteners or assembly, a hole punch ensures neat, consistent holes without tearing or fraying edges.

8. Paper Clips or Binder Clips

For holding the template pieces together during assembly, paper clips or binder clips are a great option. They ensure all parts stay aligned while you work on the project.

9. Glue Gun or Craft Glue

For the final assembly, use a glue gun for quick bonding or craft glue for a stronger, longer-lasting hold. Apply carefully to avoid excess glue squeezing out.

Having these tools at hand will make assembling an opener from a template a quick, precise, and enjoyable task.

Test your letter opener template’s durability by subjecting it to various conditions. Begin with evaluating its resistance to wear and tear by using it regularly under normal operating conditions. Check for signs of bending, cracking, or other physical damage. A durable template should withstand repeated use without any noticeable degradation.

Simulating Real-World Use

Recreate typical scenarios where your template might be exposed to stress. For example, try opening a variety of letter types, from light paper to thicker envelopes. Pay attention to the template’s ability to maintain its shape and integrity when applied to different materials. This will provide insight into how it handles real-world pressures.

Environmental Factors

Consider testing your template’s durability in different environmental conditions. Exposure to varying temperatures and humidity levels can impact its performance. Try testing the template in both a dry and a humid environment to assess how it holds up over time. This helps ensure it performs well in various settings without compromising its durability.

Focus on functionality and simplicity. A common mistake is making the opener overly complicated. Keep the design user-friendly and easy to operate. A cluttered or overly intricate design can frustrate users and undermine the purpose of the tool.

1. Incorrect Material Choice

Choosing the wrong material can impact both durability and performance. Avoid using weak or flimsy materials that might break or wear out quickly. Opt for sturdy, reliable materials that ensure the opener lasts and functions smoothly over time.

2. Failing to Prioritize Safety

Safety is often overlooked in the rush to create an opener with a sleek design. Ensure that sharp edges are properly smoothed, and the opener has a comfortable grip to prevent accidents. Users should never feel at risk while using the tool.

Avoid excessive ornamentation that may distract from the primary goal of the opener. Focus on clean lines and practical features that make the opener efficient without overdesigning.

Use a sturdy material like cardstock or thick paper to create your letter opener template. This ensures durability and precision when tracing onto other materials. Begin by drawing a slim, elongated shape that gradually tapers to a fine point. This shape should be around 6 to 8 inches in length and no more than 1 inch wide at its widest part. Consider adding a slight curve to the blade for aesthetic appeal and improved functionality.

Next, cut out the shape with a sharp pair of scissors or a craft knife. This will serve as your basic template. For added ease, you can add a handle by extending the bottom of the shape into a wider segment, creating a comfortable grip. It’s best to keep the handle shape simple to avoid any complicated designs during the cutting process.

Once the template is complete, use it as a guide for transferring the design onto your final material. Whether you’re using wood, metal, or plastic, this template will help ensure consistency across multiple pieces. When transferring, be sure to trace gently, ensuring your lines are clear but not too deep to avoid material damage.