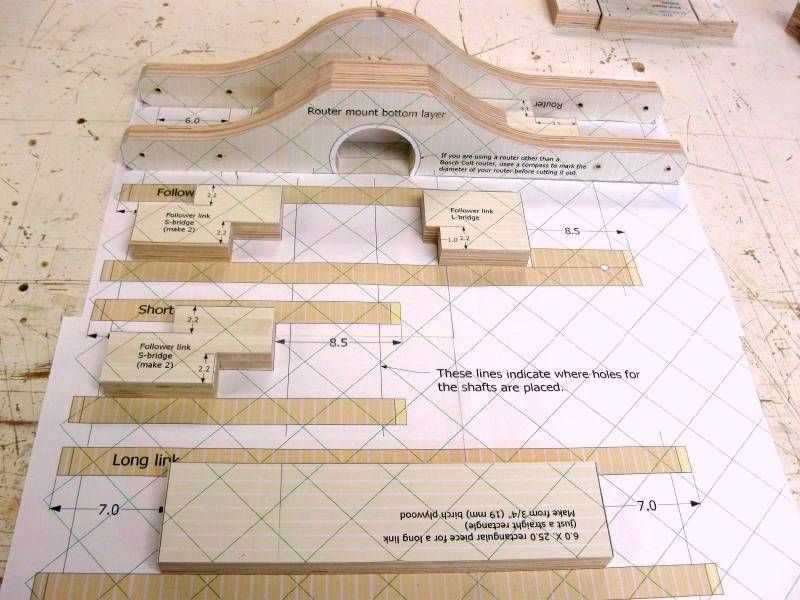

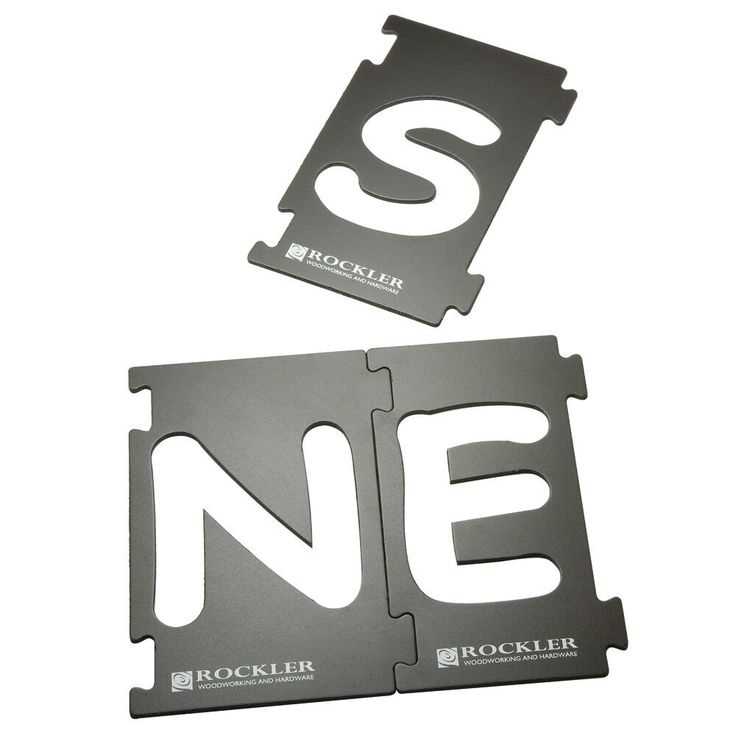

Router large letter templates

For those looking to craft large, clear lettering with a router, using well-designed templates can save time and effort. Start by selecting a sturdy material for your template, like MDF or acrylic, which will provide the durability needed for repeated use. Ensure the edges are smooth and free from any imperfections to maintain consistent letter shapes.

Accuracy is key when cutting large letters. Take your time to securely attach the template to the workpiece, using clamps or double-sided tape to prevent movement during the routing process. It’s advisable to use a router with a plunge feature, allowing you to control depth and achieve clean cuts. A sharp bit is crucial for avoiding rough edges.

If you’re working with intricate designs, break the process into manageable sections. This method not only reduces the risk of mistakes but also ensures precision in every cut. Finally, finish the edges with sandpaper to smooth out any rough spots, giving your project a polished look.

Here are the corrected lines without repeated words:

Start by ensuring each word serves a distinct purpose in the sentence. Avoid redundancy to keep the message clear and concise. Eliminate any unnecessary phrases or repeated terms. This will streamline communication and enhance readability.

For example, instead of saying “advanced high-tech devices,” use “advanced devices” or “high-tech tools” depending on the context. This keeps the sentence focused on the main point.

Double-check your content for phrases that can be simplified without losing meaning. A sentence like “modern and innovative solutions” can be simplified to “innovative solutions” or “modern approaches.” Avoid adding extra words that don’t contribute new information.

By using precise language, you help readers grasp the core idea quickly, reducing the chance of confusion. Each word should add value to the sentence without repeating the same concept multiple times.

- Router Large Letter Designs

Begin by selecting a font that is both bold and clear for the router large letter designs. The clarity of the letter edges will directly impact the final result. Opt for a stencil-style font that provides consistent spacing and easily defined contours. This ensures a smooth cutting process and precise outcomes.

For material selection, choose sturdy plywood or MDF for the best results. These materials offer stability during the routing process and produce clean, sharp edges. Avoid softer woods like pine, as they may cause splintering or uneven cuts.

When setting up your router, use a sharp bit that matches the thickness of the material. A quarter-inch spiral upcut bit works well for most designs, offering minimal tear-out. Make sure to secure the material properly to prevent any shifting while routing.

After setting the router depth, begin cutting the outline of the letters. Move at a consistent speed, allowing the router to maintain an even pace. If working with intricate designs, make multiple passes at a shallow depth rather than trying to cut everything in one go.

Finish by sanding the edges to remove any rough spots or imperfections. Use a fine-grit sandpaper to achieve smooth, even contours, enhancing the final appearance of your large letter designs. A finishing coat can also be applied to protect the letters and add a polished look.

Selecting the right tool is key to achieving clean and precise lettering. Focus on these aspects:

- Router Type: For lettering, a plunge router or a fixed-base router is ideal. Plunge routers provide better control and flexibility for intricate designs, while fixed-base routers work well for consistent, straight lines.

- Bit Selection: Choose bits designed specifically for lettering, such as V-groove or spiral bits. V-groove bits create sharp, angular lines, while spiral bits produce smooth, rounded edges.

- Size Matters: Use smaller bits for detailed work and larger ones for bold lettering. For most lettering projects, bits in the range of 1/8″ to 1/2″ are the best options.

- Material Compatibility: Ensure your tool and bits are suitable for the material you’re working with. Different woods, metals, and plastics require specific bits to avoid chipping or burning.

- Adjustability: Opt for a router with adjustable speed settings. Slower speeds are better for delicate materials, while faster speeds work for harder surfaces.

Invest in high-quality bits and ensure your router has the necessary adjustments to suit your project needs. Proper maintenance also ensures longevity and consistent results.

Begin by gathering the necessary materials: paper, pencil, ruler, and scissors. A large piece of paper will help you achieve the desired size for the letters.

Step 1: Design the Letter

Sketch the shape of the letter you want to create on a piece of paper. Ensure the letter is clear and proportional to the size you need. Use a pencil to make adjustments as needed.

Step 2: Measure and Mark

Use the ruler to measure the width and height of the letter. Mark the key points on the edges to maintain symmetry and accuracy. This will help when cutting out the template.

Step 3: Cut Out the Template

Carefully cut along the edges of the letter with scissors. Take your time to ensure smooth, straight cuts for clean edges. If you’re using a stencil material, be sure to use a sharp blade for precision.

Step 4: Trace the Template

Place the cut-out letter on the surface where you want to create the letter. Trace around it with a pencil to get the outline. This will guide your final application of the letter shape.

Step 5: Final Adjustments

If necessary, make any final adjustments to the letter’s shape, ensuring it’s the correct size and proportions. Once you’re satisfied, your template is ready to be used for any project.

To achieve sharp, clean lettering, begin by fine-tuning the router’s depth of cut. Shallow cuts help maintain accuracy, reducing the risk of overcutting. Start with a light pass and gradually increase the depth until the desired result is achieved. This minimizes the chance of damaging the material or creating rough edges.

Speed Control

Adjust the router speed according to the material you’re working with. Slower speeds are better for harder materials, as they reduce the risk of the bit burning the wood or causing uneven cuts. Conversely, faster speeds are ideal for softer materials, allowing the bit to move smoothly through the surface.

Bit Selection

Choose a bit with a fine edge for precision work. A sharp, high-quality bit will ensure smooth cuts and prevent fraying, especially around tight corners. For intricate lettering, opt for a smaller diameter bit to maintain fine details and avoid excessive material removal.

Hardwood is an excellent choice for large-scale routing projects. It offers a dense, smooth surface that holds intricate details well, making it ideal for routing precise patterns and designs. Popular hardwoods like oak, maple, and cherry are known for their durability and resistance to wear. These materials ensure that the router bit remains sharp and the cuts are clean over time.

Medium-Density Fiberboard (MDF) is another solid option. Its smooth, even surface makes it easy to achieve consistent results when routing. MDF also provides good stability and is less prone to warping, making it an ideal material for detailed work and larger projects that require uniformity. However, MDF can produce more dust, so proper ventilation or dust collection systems are recommended.

Plastic Composites like acrylic and PVC are also popular for routing large letters. Acrylic is particularly well-suited for clean, sharp edges and vibrant finishes, while PVC can be routed into various shapes without cracking. These materials are often used for signage and decorative routing due to their flexibility and ease of use.

Aluminum is another material that handles large-scale routing well. It provides excellent rigidity and strength, especially for precision routing. However, routing aluminum requires specialized router bits designed for metalworking to prevent overheating and maintain clean cuts.

Choosing the right material depends on the project’s specific needs, including durability, finish quality, and routing complexity. Always ensure the material you select is compatible with your router and bits to achieve the best results.

One of the most common challenges when working with large letter templates is maintaining consistent depth and width. To solve this, use a guide rail or fence on your router to ensure even cuts across the entire design. Double-check your measurements and make adjustments as needed to keep the letter proportions accurate throughout the process.

Uneven Edges

Uneven edges often occur due to inconsistent speed or pressure during the routing process. To prevent this, maintain a steady hand and consistent speed. Using a plunge router with a soft-start feature helps reduce abrupt changes in speed, which can affect edge quality. Regularly inspect your work to spot any irregularities early on, ensuring smooth, uniform results.

Inconsistent Letter Alignment

Alignment issues can arise when transferring the template onto the material. Secure the template firmly with clamps or double-sided tape to avoid shifting during routing. If necessary, lightly score the edges of the letters with a pencil before routing to guide the process. Taking the time to align the template properly saves time on adjustments later.

By focusing on preparation, steady technique, and proper tool use, these challenges can be easily managed, leading to clean, precise lettering results.

Clean your router after each use to prevent buildup of dust and debris that can affect performance. Use a soft brush or compressed air to clear the motor, collet, and bit area. Never use water to clean electrical components, as moisture can cause damage.

Regular Lubrication

Lubricate the moving parts of your router, such as the motor shaft and collet. Apply a small amount of lubricant recommended by the manufacturer to prevent friction and wear. Check the manufacturer’s guidelines for specific recommendations on lubricants.

Inspecting and Replacing Bits

Inspect your router bits for signs of dullness or damage after each project. Replace worn bits promptly to ensure clean and precise cuts. Storing bits properly in a case will protect them from rust and damage.

Storage and Handling

Store the router in a clean, dry place to avoid exposure to moisture and dirt. Always disconnect the router from power when not in use to prevent accidental operation. Handle the tool with care to avoid impact that could misalign internal components.

Table: Router Maintenance Checklist

| Action | Frequency |

|---|---|

| Clean the router | After each use |

| Lubricate moving parts | Every 10-15 uses |

| Inspect and replace bits | After each project or when dull |

| Store in a dry place | Always |

To create precise and clean large letter templates with a router, start by securing the material on a stable surface. Use a guide to outline the letters, ensuring the router follows the correct path. Adjust the depth of the router bit according to the thickness of the material. For sharper edges, use a finer router bit and make gradual passes to avoid splintering. After outlining the shapes, carefully remove any excess material within the letters, always keeping the router moving steadily to maintain consistency.

For intricate designs, consider using a pattern or stencil. This ensures that even small details are maintained. Double-check the edges of your template before starting to make sure the lines are clear and free from any mistakes. If you’re working with wood, smooth the edges after cutting with sandpaper to refine the letter shapes and give a polished finish.

Finally, test the template on a scrap piece of material before committing to the main project. This allows you to make adjustments to the router settings if necessary and avoid errors on your final piece.